Straight to the point: Why do signs cost so much? Read along, friends. I’m not one that minds explaining myself, and neither am I a gate keeper. A matter of fact, if there is somebody reading this who is starting their trek into this realm, I’d be pleased to learn they learned something from me!

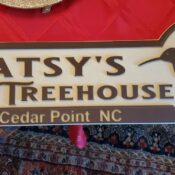

I live on the coast, and much of my effort is for homes on the beach- rentals, as they are- for vacationers. A home such as that needs a name, no? And, for the fun of it, so do rooms/suites. It just makes it a little more interesting.

The anatomy of a sign… anyone with a cnc can carve one, but are they made right? Will they last? These will. Buy from who you want when you’re in the market, but make sure you’re getting something more than just “pretty”… make sure it’s made right….sealed right… provisions to be mounted right. If you’re told those things don’t matter and only the appearance does, you may want to spend your hard earned money with someone who disagrees and places equal attention on elements that make it a truly quality piece.

In this environment, there are really only three substrates I will work with. Before those are given, though, I’ll tell you what I will NOT work with and why…

Acrylic is great, but if it isn’t UV printed, there are no vinyl prints that will survive even two years in the sun, here, without lamination. Even with lamination, you’re looking at no more than five years. And how else do you decorate acrylic? For this reason Vinyl is out, and it took acrylic with it… caveat: I use acrylic for accents and letters often and they do very well here and just about anywhere else, and, UV printed acrylic works well in this area SO LONG AS it’s printed on the inside of the fixture…. it lacks dimension, though, no matter how you slice it.

Again, vinyl is out because of the above^ .

Wood- even Cyprus- just doesn’t last. For dimensional signs it is the flagship- the high water mark- the classic… but here? Unless you stay on top of it and I mean really on top of it, wood won’t last. Looks? Spectacular in the beginning, and if well kept. It’s just not as some of the other substrates, so I exclude it… There is a caveat here as well: I make the carved/dimensional signs ‘look’ like wood, so that classic look is retained.

What WILL I work with?

King Color Core- which is two (or three) colored and layered HDPE, and HDPE is maybe the toughest material for signage there is in terms of lasting. However, it warps when used in large sections so it has to be backed with something substantial- either mounted to a flat surface, or with a flat surface mounted to it. The thickest reasonable Color Core is 3/4″ thick, and nothing sticks to it at all. It has to be mechanically affixed to it’s mount, and no paint made will bond to it, so you’re stuck with two (or three) tones of generic colors and only slight dimensional appeal. However, it will last forever with little to no maintenance.

Expanded Closed Cell Foam Sign Grade PVC works very well with dimensional signage. It carves spectacularly and it easily accepts many kinds of paint. It moves a little, so care must be taken with tolerances and compensated for. It usually requires a backing, and most often I used max-metal- a corrugated metal and plastic material- to do the job. It is much cheaper than HDU and Color Core, though not near as tough as either (when properly treated). It does, however meet every other requirement I have, so… I use it often. Put it like this: A sign that costs $375 from my shop in PVC is a quarter of the price of the same in HDU- though it will only last half as long. The economics say “use pvc”. There are some cases where I recommend HDU, but they are few when PVC can do the same job.

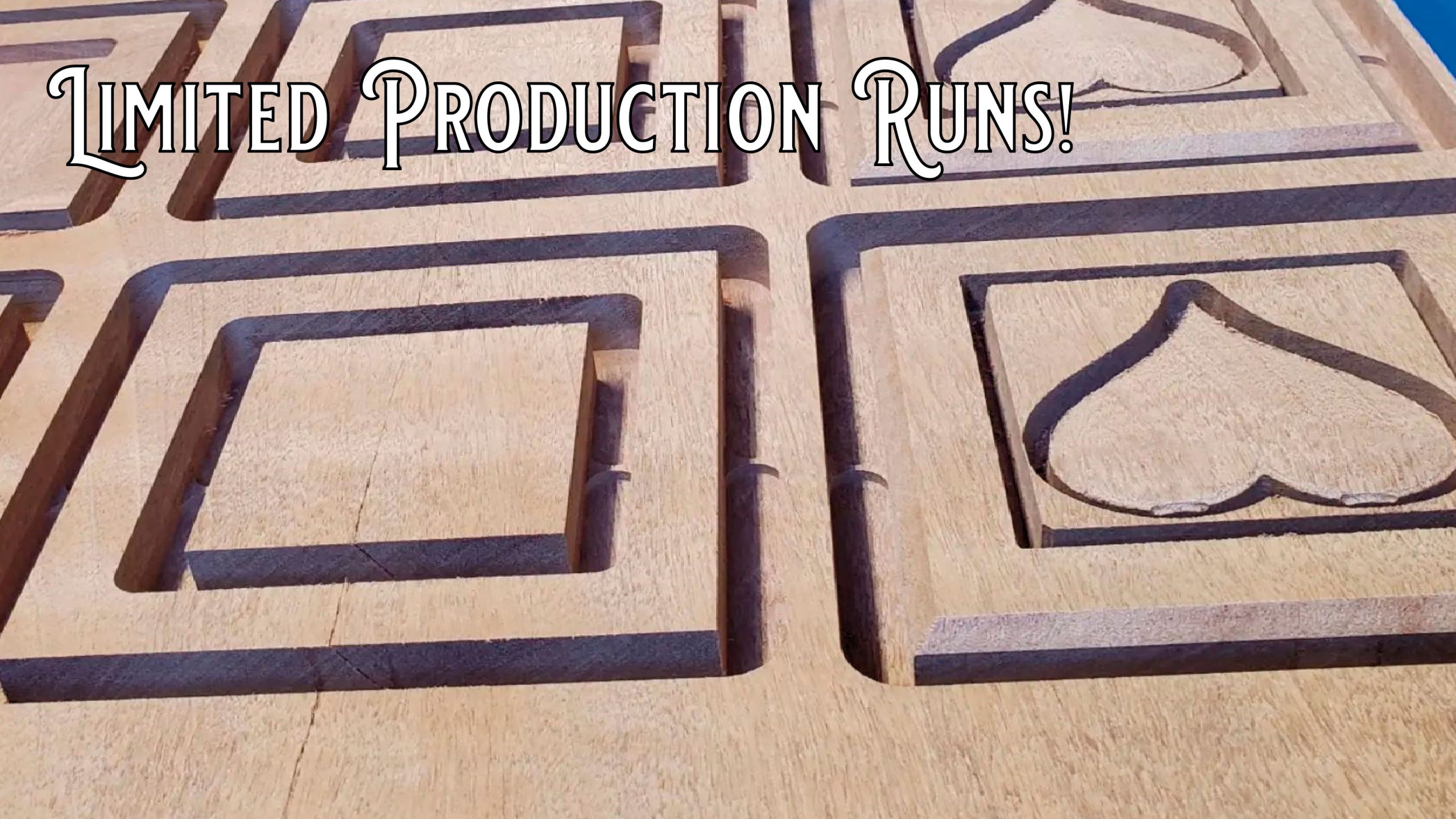

HDU is the best of the material available for carved or dimensional signs. It is a dense closed cell foam which is incredibly consistent. There is nothing that carves better. Nothing. The tiny details that can be revealed while carving puts this material in a realm of its own. However- the cost is only it’s first con. It has to be primed and painted. Sure, lots of people use latex paints on it with some success, and others use enamel. I’ve even used acrylics and seals. But, HDU really shines when using automotive paints and clearcoats. Not only for it’s looks, but because those paints make HDU carved signs tough and resilient to weather and washes in the same way your car looks good for years with the same treatment. You can guess, though, that a proper HDU sign, painted, clear coated, backed (it’s a VERY good idea to ‘back’ HDU, too- and either acrylic or MaxMetal works beautifully. ) and installed is very often at least a five figure job. Meaning, five positions of $’s before the cents…

Those, friends, are the substrates used most often ’round these parts.

Here is HOW they’re used and in the case of a ‘beach house’ sign.

First, I select PVC in one inch thickness. From this, I will carve a design if needed, and carve letter independent of the main sign board. The background of the design is often carved to look as wood- this is down to a science at this point and folks can even choose which grain/species of wood they prefer to imitate. Again, letters are a separate aspect so the panel is only carved with pockets to receive the letters as insets.

The letters are carved and rounded/crowned, and with enough ‘wiggle room’ to mitigate expansion and contraction due to weather changes. Because they’re carved separate, beautifully crisp lines are possible between the panel and the lettering. It simply can’t be done as well if the sign is one piece. Having the lettering separate also allows an opportunity to hide the mounting hardware. That’s actually hugely beneficial and a reason to separate the letters from the panel all by itself…. until you realize how pretty those crisp lines are, and how easily achieved compared to painting them whole.

Once painted, a huge trick for this environment involves (drumroll) …… RESIN… Everything is set in resin. Everything except the backing of the sign…

The backing is there to provide a strong surface for mounting and to exponentially increase the signs durability. It is FAR more rigid with a simple shaped MaxMetal backer.

The mounting of the sign is done via stainless lag bolt and accessed from under the first and last letters of the sign. For those letters I use a mild adhesive to hedge my bet, but the letter fit snugly into one quarter inch deep pockets (as all of them do, it’s just these particular ones use mild adhesive as opposed to locking adhesives) so they can be removed without breaking them if the sign needs to be relocated or replaced. This provides a clean look for the install.

Also, this one is intended to be mounted to the side of a house with overlapping side boards. Because of this I will use one inch barrel standoffs to ‘float’ it above the surface. This will ensure the signs face will remain flat aka perpendicular to the ground, and it will mitigate any water running off the wall ensuring it doesn’t find a path over the sign face thus dirtying it.

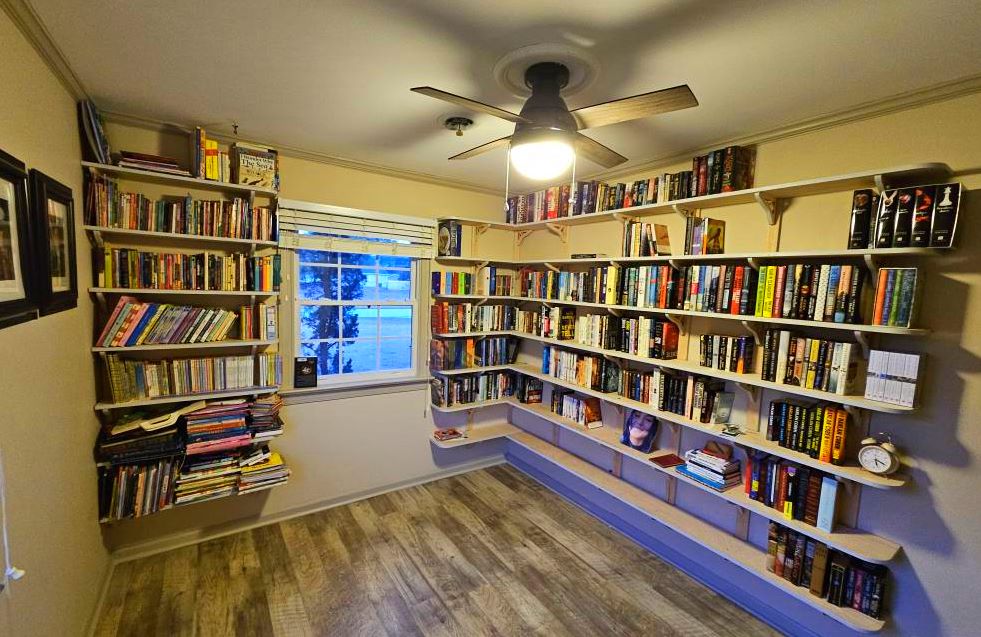

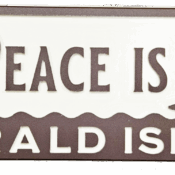

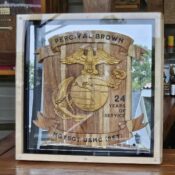

The ‘suite signs’ are of wood. These are intended for interior work, so a seal of poly was all that was needed. The back of these has a form cut adhesive panel of 3m468mp, the best adhesive for this purpose made. Note in the images the adhesive doesn’t go all the way to the edges, ensuring it remains unseen, and, by it covering the entirety of the sign (except for the very edges) it will add some strength to the sign ensuring it last for years and years, guarded against bumps and impacts.

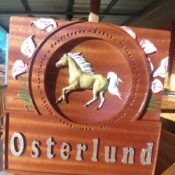

I’m a visual type dude, and I’m going to guess y’all are too as you’re interested in signs- So- I’m going to shut up now and show you pictures of what I just spoke about, with an additional shot of two small pine signs that go on Suite entrances. They’re pine panels with PVC carvings inset and with 3M double sided adhesive on the backs as a mounting option. The opening line was “why do signs cost so much?” is better explained using the images and allowing folks to grasp the effort that goes into making them, when they’re made correctly.